Modern manufacturing runs on automation. Robots assemble cars, sensors track inventory, and software controls entire plants. For engineering students, learning how these systems work is no longer optional—it’s a smart move for building a successful career. Certified online automation training offers a flexible, industry-focused way to get ahead.

Why Industrial Automation Skills Matter for Engineering Students

Manufacturing and processing industries invest in automation to cut costs, boost efficiency, and improve safety. Companies need people who can design, program, and maintain these systems. That demand continues to grow each year.

Automation skills help students step into roles with clear career paths. Automated factories run faster and safer, but they need smart people to keep things moving. Whether working with assembly lines, packaging facilities, or process plants, knowledge in automation unlocks more job options.

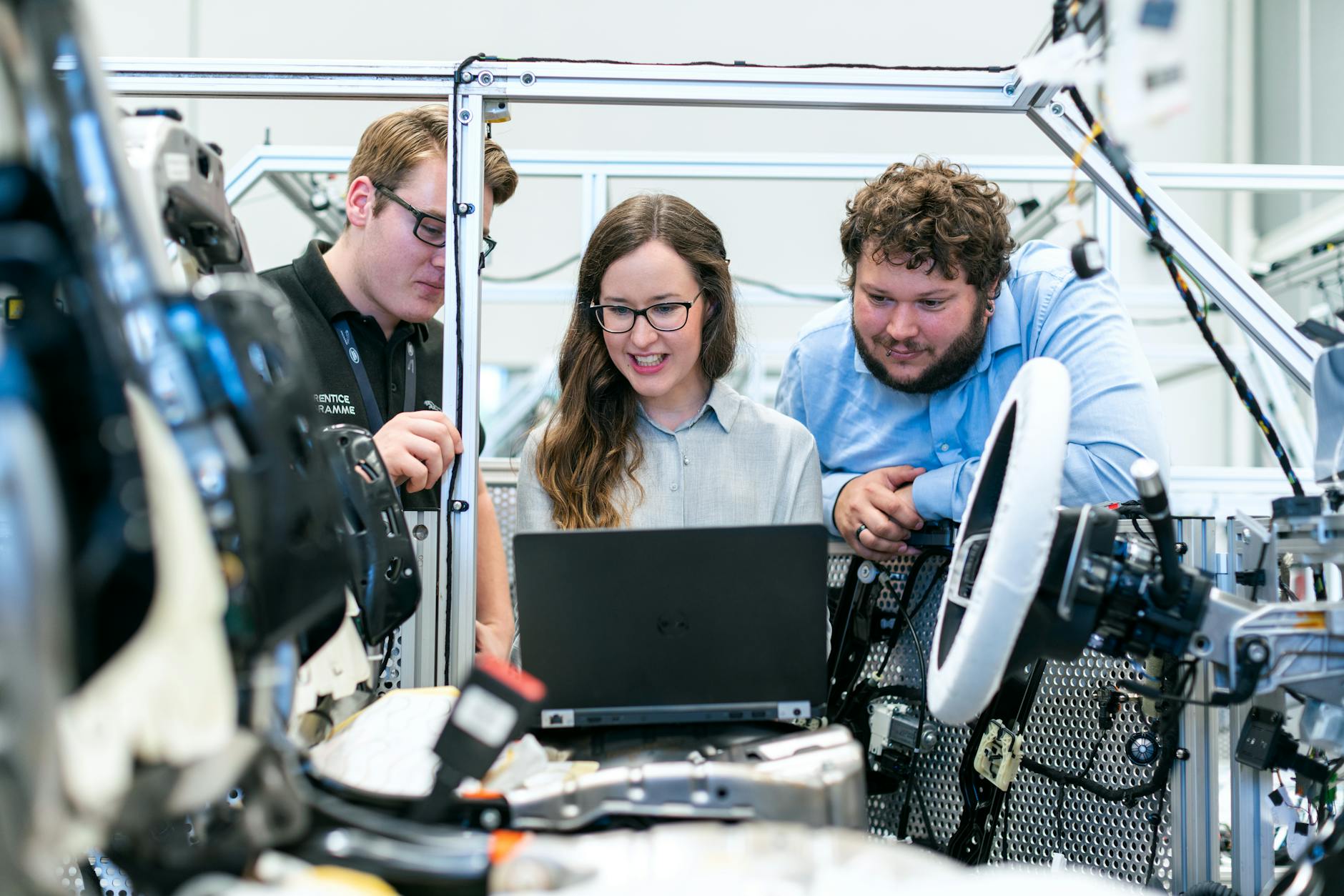

Photo by ThisIsEngineering

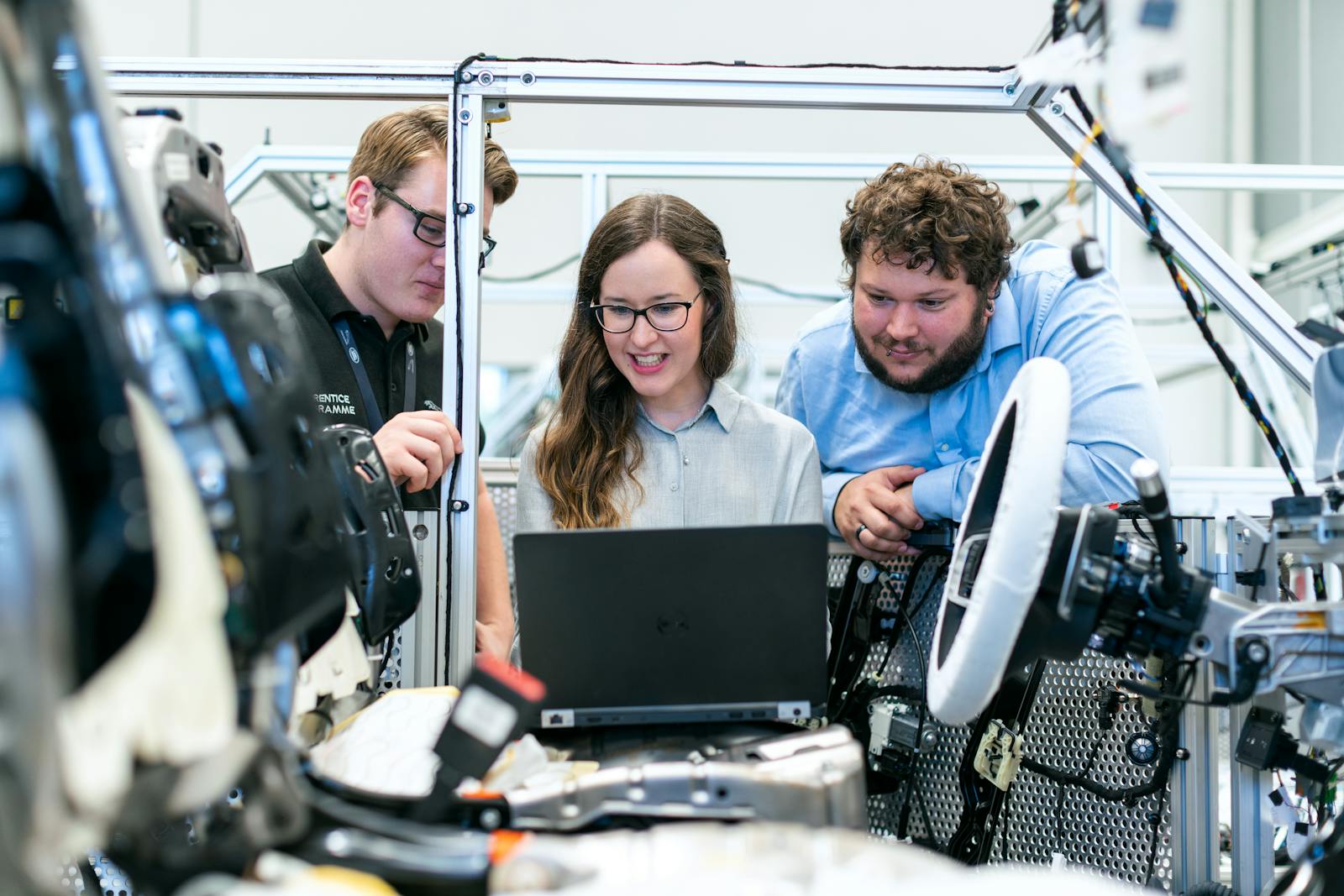

Photo by ThisIsEngineering

Industry Demand and Job Outlook

Automation drives hiring across sectors. According to recent reports, jobs in automation are among the most in-demand in engineering. There are shortages in skilled roles related to robotics, industrial control, and digital manufacturing.

Real-time feedback from industry professionals points to strong growth in markets from pharmaceuticals to energy. Recruiters often contact automation specialists multiple times each week, especially in high-demand regions and industries (source). The demand creates steady job prospects with room for career growth.

The gap between available jobs and qualified candidates is clear. Insightful studies highlight that companies often struggle to fill automation-related positions due to a lack of trained applicants (Bridging the Workforce Gap in Industrial Automation).

Key Technologies in Automation

Understanding industrial automation involves working with a reliable set of technologies:

- PLCs (Programmable Logic Controllers): The brains of automated machines and production lines.

- Robotics: Systems that handle sorting, assembling, and transporting products safely.

- SCADA Systems (Supervisory Control and Data Acquisition): Platforms that monitor and control entire operations in real-time.

- IIoT (Industrial Internet of Things): Connecting machines, sensors, and software for smarter monitoring and data gathering.

- Industrial Control Systems: Including drives, actuators, and process instruments.

These tools are the backbone of modern factories. Mastering them sets engineering students apart.

What to Expect from Certified Online Automation Training

Certified online programs teach students the skills companies want. Courses are practical and job-oriented, often developed with input from engineers in the field. The flexible format lets students learn at their own pace while working toward respected industry credentials.

Online training platforms like the Industrial Automation Technician Program or RealPars deliver interactive modules, real-world projects, and simulation tools to reinforce learning.

Course Topics and Learning Path

Online automation courses cover a range of subjects that build from basics to advanced concepts. Students can expect modules such as:

- Digital electronics and industrial wiring

- PLC programming and troubleshooting

- Robotics basics and integration

- Process control strategies

- Industrial network communications

- Cybersecurity focused on standards like ISA/IEC 62443

- Simulation and hands-on practice

These modules help students learn the how and why behind automated systems, not just the theory.

Industry-Recognized Certifications

Certifications make a difference. Employers value proven skills, and industry credentials help students stand out. Some respected certifications include:

- Certified Automation Professional (CAP): Focused on automation and control system deployment.

- Certified Control Systems Technician (CCST): Recognized by industry leaders for hands-on control system skills.

- SACA Industry 4.0 Associate: Addresses modern smart manufacturing requirements.

These certifications match the skills taught in quality online courses. They signal to employers that a candidate is work-ready and up to current industry standards.

Hands-on Skill Development Online

A strong online automation program doesn’t skip practical experience. With the help of:

- Integrated simulations,

- Virtual labs,

- Interactive PLC programming exercises,

- Case studies from real production environments,

Students can practice troubleshooting and programming industrial systems, all from their laptops. Many platforms, like ASME’s Industrial Automation Courses, offer 24/7 access, letting students learn when it fits their schedule.

Conclusion

Industrial automation is changing how the world makes products, and that change requires smart, trained people. For engineering students, certified online automation training offers the knowledge, hands-on skills, and industry credentials that top employers seek.

As automated factories and digital systems continue to grow, those who bring strong automation skills will have the edge. Choose a certified online program, put in the work, and watch as opportunities open up. The industry needs talent—now’s the time to stand out.

Frequently Asked Questions

What will I learn in this course?

This course covers key industrial automation topics. You will gain knowledge in control systems and programming. It prepares you for real-world automation challenges.

Is this training accredited?

Yes, this training leads to a certification. Our certification is recognized in the industry. It validates your automation skills.

What are the prerequisites for this course?

Some basic technical knowledge is helpful. Experience with electrical or mechanical systems is a plus. No prior automation experience is required.

How long does the online training take?

The course duration varies by individual. Most students complete it within a few weeks. You can learn at your own pace, fitting it into your schedule.

What equipment do I need for the training?

You will need a computer with internet access. Some exercises may require specific software. Software download instructions are provided.

Will I get hands-on experience?

This online course uses simulations. These simulations mimic real automation equipment. They provide practical application of learned concepts.

h6lw9r