Industrial automation is made possible with PLCs. PLCs are used in machinery, processes, and manufacturing systems; energy and transportation; and other industries. PLC programming is for freshers and engineering students who are new to the automation industry. PLC SCADA blog: Learn how it works, how to use it step by step, and why it plays a vital role in smart automation technology

PLC is Programmable Logic Controller.

A Programmable Logic Controller (PLC) is a rugged digital computer that humans manufacture for industrial surroundings. It looks at inputs and controls based on a pre-programmed logic and sends a control of outputs to train machines or the flow of procedures.

Key Features:

Robustness: Built to operate under severe conditions (dust, moisture, vibration, and so on). Real-time operation: Processes logic in real-time order to have accurate control. Modularity design: More input/output modules of PLC can expand it.

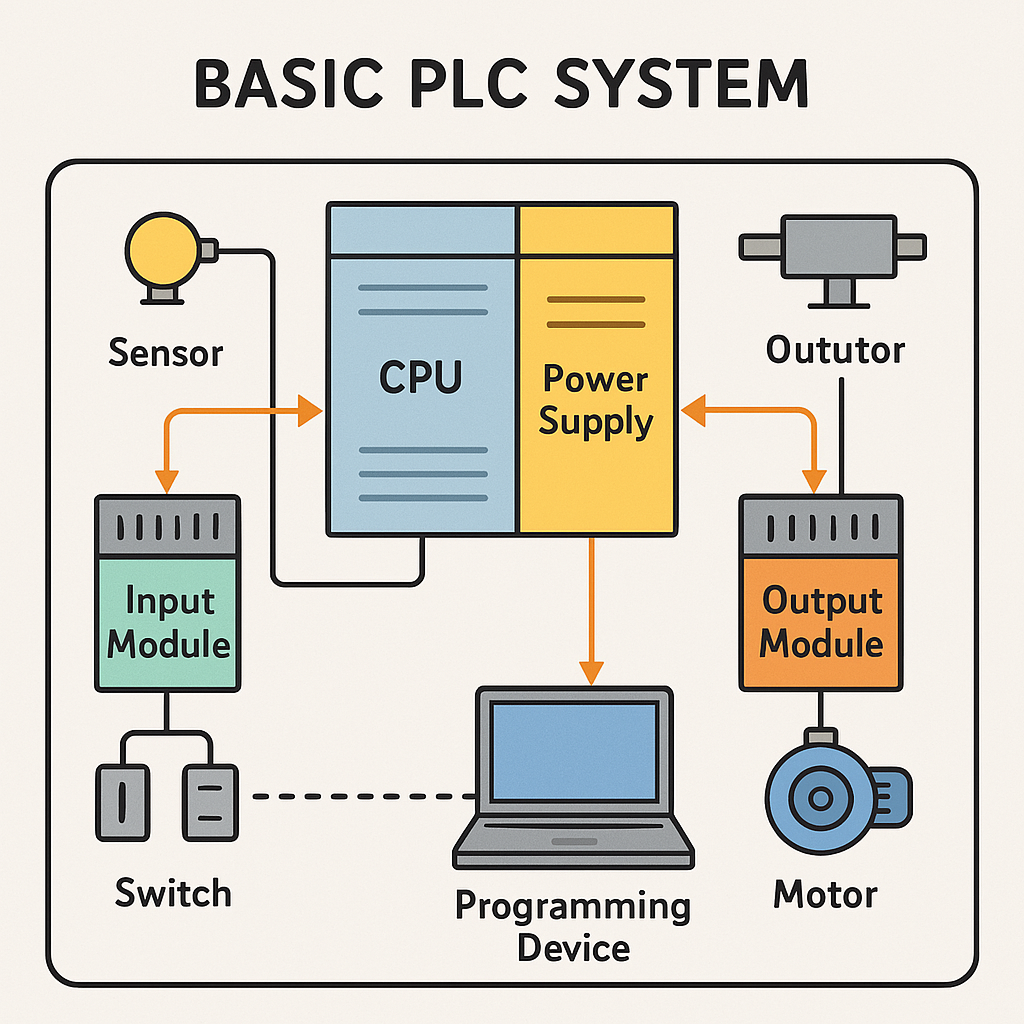

Simplified Elements of PLC System:

CPU (Central Processing Unit)

- The PLC brain.

- Performs control instructions within memory.

Power Supply

- Supplies energy to the PLC and PLC modules.

Input Modules

- Get signals of sensors, switches, etc.

- Put them in a form the CPU can understand.

Output Modules

- Send control commands to each actuators, motor, etc.

Programming Device

- A laptop or a handheld is used to communicate and program the control program into the PLC.

The Way PLCs Operate:

The process of a PLC occurs in an endless cycle referred to as a scan cycle:

- Input Scan: Scans the status of any input device.

2. Program Execution: The program forces the logic written by the user, depending on the input status.

3. Output: Changes output device status.

4. Housekeeping: Conducts in-house inspections and messages.

PLC Programming:

The design of PLCs is done by specialized languages that obey a standard IEC 61131-3. The most typical ones are

-

Ladder Logic (LD)

- Bears similarity to electrical relay logic diagrams.

- Simple enough to be read by electricians and technicians.

2. Function Block Diagram (FBD)

- Represents functions and connections by the use of blocks.

- It is suited for use in process control.

3. Structured Text (ST)

- Language with a high level, like Pascal.

- Applicable to highly sophisticated algorithms.

4. Quicksort IL (Instruction List) and SFC (Sequential Function Chart)

- Less popular but still advocated by a lot of PLCs.

Simple Ladder Logic:

Consider a system of the sort that a motor is expected to run on pressing a start button and should stop when a stop button is pushed.

|----[ Start ]----+----[/ Stop ]----( Motor )----|

|

+----( Latch )-------------------|- [ Start ]: Normally open push button.

- Stop ]: uninterrupted contact with the fail-safe push button.

- (Motor ): vehicle scadimento.

- (Latch ): causes the motor to continue running after the start button has been released.

Uses of PLCs:

The application of PLCs is a lot more diverse:

- Production: Assembly lines of factories, robotic manipulators.

- Power Plant control: Energy.

- Pump and valve control: Water treatment.

- Transport: Traffic light systems and railway automation.

- Building Automation: Heating, ventilation, and air conditioning; elevated light control devices.

The benefits of the use of PLCs The benefits of using PLCs are as follows: a very rapid installation process very high degree of reliability

- Flexibility: Adapts very easily to other functions.

- Reliability

- Scalability: It is possible to expand it with other modules.

- Cost-effective: Eliminates the heavy wiring and relays.

Introduction to PLCs:

If you are excited to learn, take a close look at the guide below

- choosing a PLC brand: Siemens, Allen-Bradley, Mitsubishi, etc.

- Install the simulation program: There are numerous free software brands.

- Get familiar with ladder logic: use simple projects at first.

- Real hardware drills: Try to obtain a training kit.

- Search for free and paid courses as well as tutorials: Google offers a lot.

Recommended Resources:

- Books: “ Programmable Logic Controllers”” by ”Fran D. Petruzella

- Udemy, Coursera, and plc academy online Courses

- Simulation Software: LogixPro, TIA Portal, CX-Programmer

Wishing you very happy career growth!