What is the PLC and Used in Industrial Automation: A Complete Guide

Learn about the variants of PLCs in industrial automation, such as modular PLC, compact PLC, rack-mounted, and soft PLC. Get familiar with its applications and benefits, as well as the process of picking the right PLC depending on your automation requirements.

Introduction:

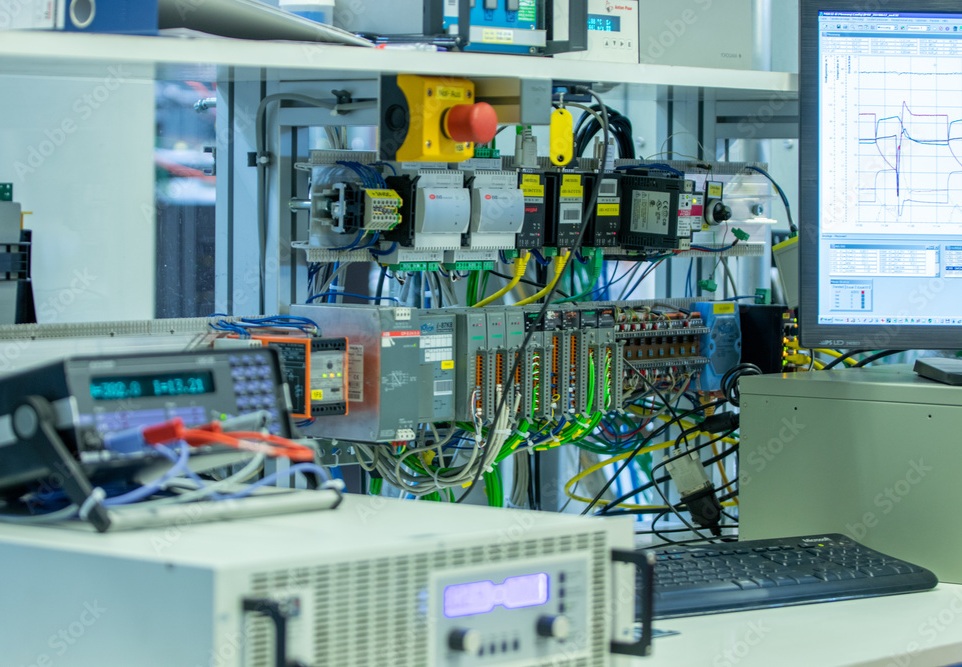

Programmable Logic Controllers (PLCs) are significant in the industrial automation industry, as they have to do with the control and monitoring of machinery and processes. These ruggedised digital computers are very popular in other industries such as manufacturing, power plants, auto, food processing, and so on. Not all PLCs are alike, though. There exist different kinds of PLCs, each adapted to serve a certain industrial need.

As we read this article, we shall be examining the key kinds of PLCs categorised as applied in industry automation, their characteristics, utilisation, and variations to distinguish them.

1. Compact PLCs (Integrated PLCs)

Definitions:

Integrated or compact PLCs are installed in very small sizes; they have fixed input/output modules. They can be perfectly used in basic automation applications.

- Key Features:

- Determined number of I/O points

- Integrated power supply, central processor, and communication ports

- Cheaper and small-sized

- Convenience of installation and ease of maintenance

- Convenience of installation and ease of maintenance

Applications:

- HVAC systems

- Packaging machines

- Small-scale conveyor systems

Automatic control panels and lighting Automatic lighting and control panels

Compact PLC, integrated PLC, basic PLC, small PLC systems

2. Modular PLCs

Definition:

The modular PLCs are made of individual modules like CPU, power supply, input/output modules, and communication modules that can be removed or added according to the need.

Key Features:

- Very scalable and flexible

- High in upgrade-ability or expand-ability

- Cats to any numerous varieties of I/O modules

- Appropriate to complicated systems

Applications:

- Manufacturing lines

- Process automation

- Water treatment works

- Automation in an assembly line

Modular PLC, flexible PLC systems, scalable PLC, industrial PLC modules

3. Rack-Mounted PLCs

Definition:

A rack-mounted PLC is a modular PLC, such that all modules are on a rack system. They are applied to automation high-end and large scale.

Key Features:

- Multiple CPU and high I/O supported

- Bandwidth/redundancy and high-speed communication

- Unaffiliated with distributed control systems

- Is capable of modifying complex motion and logic control

Applications:

- Oil & Gas automation

- Automotive manufacturing

- Huge generators of power

- Production systems of pharmaceuticals

Rack-mounted PLC, large-scale automation, high-performance PLCs, advanced industrial PLC

4. Soft PLCs (Software-based PLCs)

Definition:

Soft PLCs are achievable software applications that operate under industrial PCs, through which they have equal functionality as the hardwired PLC counterparts.

Key Features:

- Runs on normal computers

- SCADA and HMI Integration is easy

- Wide distributed systems friendly In terms of cost-efficiency

- Enables features of real-time control via industrial Ethernet

Applications:

- Smart factories (Industry 4.0)

- Control systems based on SCADA SCADA-based control systems

- The data center controls the distribution

- Artificial intelligence and cloud services integration

Soft PLC, software-based PLC, PC-based control systems, Industry 4.0 automation

5. Nano and Micro PLCs

Definition:

They are ultra-miniature PLCs having inferior I/O facilities suitable for very tiny automation projects.

Key Features:

- Very small in size

- Less energy consumption

- Few memory and limited processing capacity

- Budget-friendly solution

Applications:

- Home automation

- Basic control of machinery Simple machinery control

- Educational labs and test-setups

- Small electronic appliances

Nano PLC, micro PLC, mini PLC controller, low-cost PLC systems

How to Choose the Right Type of PLC:

These are the things to consider when choosing a PLC to implement on your industrial automation project:

- System complexity (number of devices and sensors)

- I/O requirements (Digital, analog, or Special modules)

- Protocols of communication (Ethernet/IP, Modbus, Profibus)

- The conditions of the environment (temperature, humidity, dust)

- Scalability and budget

Ensuring that you match the appropriate kind of PLC to what you need in your industrial operations guarantees adequate performance and a cut in maintenance costs as well as overall reliability.

PLC selection guide, best PLC for automation, how to choose a PLC, PLC buying tips

Popular Related Topics:

- Modular PLC vs. compact PLC difference

- What is the most suitable PLC in industrial automation?

- Best PLC brands 2025

- Beginner PLC programming Systems

- based on industrial control PLC

Best of luck, and thank you!